Top 10 Steel Scaffolding for Sale Options You Should Consider?

In the world of construction, the demand for steel scaffolding for sale has surged. Industry expert John Smith states, "Choosing the right scaffolding can impact safety and efficiency." This rings especially true as projects vary in size and complexity. Selecting a proper scaffolding option is not merely a checklist task; it's a significant decision.

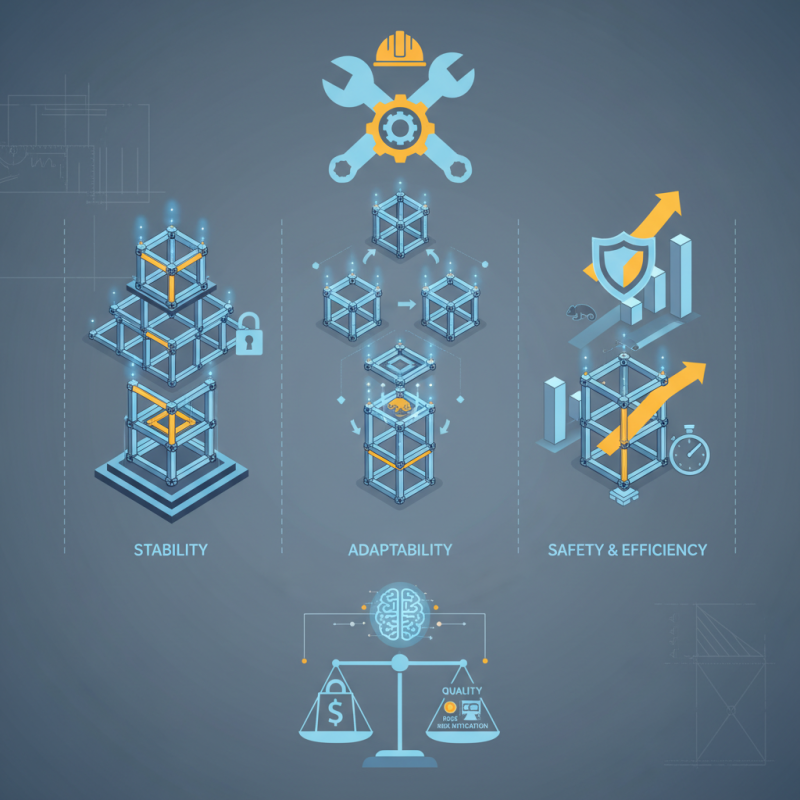

Many contractors find themselves overwhelmed by choices. With numerous types available, familiarizing oneself with each option is essential. Each scaffold serves unique needs. Some excel in stability, while others enhance adaptability. This variety prompts reflection on the specific requirements of your project.

Ultimately, understanding your options is critical. A poor choice can lead to safety hazards and increased costs. Many overlook the importance of quality over price. Investing in well-reviewed steel scaffolding can mitigate risks. Aim to balance cost, safety, and efficiency when exploring steel scaffolding for sale.

Top 10 Steel Scaffolding Options for Quality and Durability

When considering scaffolding, quality and durability are key factors. Steel scaffolding stands out for its strength and reliability. According to industry reports, steel scaffolding can support weights up to 440 pounds per square foot. This makes it ideal for heavy construction projects. However, not all steel scaffolding is created equal.

Look for models that meet safety standards. Inspect the welds and joints carefully. Poor quality welds can compromise structural integrity. Additionally, regular maintenance is crucial. Rust can weaken steel, so ensure that your scaffolding is treated with anti-corrosion coatings.

Remember, weight capacity isn't the only concern. Stability is essential too. Scaffolding should be on solid, level ground. Use base plates and adjust the leveling jacks to ensure support. Neglecting these details can lead to accidents.

When selecting scaffolding, consider portability. Some models are lightweight yet strong. This can make transport easier on job sites. An efficient setup saves time, but be wary of cutting corners. A rushed installation often leads to safety issues down the line.

Key Features to Look for When Choosing Steel Scaffolding

When selecting steel scaffolding, consider key features that impact safety and efficiency. Weight capacity is crucial. A reliable scaffolding system should hold up to 500 pounds per square foot, based on industry standards. This ensures stable support for workers and materials.

Material quality matters too. Look for high-grade steel that can withstand harsh weather. Reports indicate that scaffolding made from durable steel lasts longer and requires less maintenance. Rust resistance is another feature to prioritize. Scaffolding exposed to moisture should have protective coatings. This can significantly prolong its usage.

Lastly, ease of assembly is vital. Many systems on the market now offer user-friendly designs. Easier assembly reduces labor costs and time on-site. Consider height adjustability as well. Adjustable scaffolding allows for versatility across different projects. However, some designs complicate the building process. Reflect on these challenges to make an informed choice.

Comparison of Prices and Brands in the Steel Scaffolding Market

When exploring the steel scaffolding market, it's vital to analyze prices and options. Various types of steel scaffolding can meet your project needs, but prices can vary significantly. Factors such as design, weight capacity, and material quality often influence cost. You might find basic models at lower prices, but those may lack durability. Investing a bit more can often yield sturdier and safer scaffolding.

Different brands offer distinct advantages and drawbacks. Some might focus on innovation, while others prioritize affordability. It’s common to see price ranges from a few hundred to several thousand dollars. Make sure to check the specifications carefully. Some scaffolds may seem cheaper upfront but require more maintenance. Durability and safety features are often worth the extra expense.

As you compare options, reflect on your project requirements. It’s crucial to balance budget constraints with safety standards. Sometimes, cheaper options can lead to unforeseen issues on-site. Inform yourself about your choices. Take the time to read reviews or ask for recommendations. Analyze your needs, and choose wisely.

Top 10 Steel Scaffolding for Sale Options You Should Consider

| Option | Material | Height (ft) | Load Capacity (lbs) | Price Range ($) |

|---|---|---|---|---|

| Aluminum Scaffolding | Aluminum | 10 | 600 | 300 - 500 |

| Steel Frame Scaffolding | Steel | 12 | 1000 | 400 - 700 |

| Rolling Scaffolding | Steel | 8 | 500 | 250 - 450 |

| Modular Scaffolding | Steel | 15 | 1200 | 600 - 900 |

| Aluminium Folding Scaffolding | Aluminum | 6 | 300 | 200 - 350 |

| Steel Mobile Scaffolding | Steel | 10 | 700 | 380 - 550 |

| Heavy-Duty Scaffolding | Steel | 20 | 1600 | 800 - 1200 |

| Industrial Scaffolding | Steel | 18 | 1500 | 900 - 1400 |

| Lightweight Scaffolding | Aluminum | 8 | 400 | 150 - 250 |

| Multilevel Scaffolding | Steel | 30 | 2000 | 1000 - 1600 |

Safety Standards and Regulations for Steel Scaffolding Usage

Steel scaffolding is essential in construction, and safety standards are critical. According to the Occupational Safety and Health Administration (OSHA), around 65% of construction accidents involve scaffolding. Compliance with standards is non-negotiable. The American National Standards Institute (ANSI) outlines key requirements for design and load capacity.

It's crucial to ensure proper training for workers. Many incidents arise from improper use or lack of guidance. A study revealed that 32% of scaffold-related accidents occurred due to inadequate training. Regular inspections are vital. Inspecting scaffolding before use can prevent up to 50% of accidents.

Maintaining safety equipment is equally important. Corrosion or damage reduces the scaffold's structural integrity. The National Institute for Occupational Safety and Health (NIOSH) recommends using specific materials that can withstand environmental factors. Well-maintained scaffolding can support heavy loads and improve worker confidence. Ignoring safety standards leads to tragic consequences.

User Reviews and Recommendations for Top Steel Scaffolding Models

When considering steel scaffolding, user reviews are a goldmine of insights. Many users report satisfaction with durability and safety. However, some threads reveal concerns about weight and assembly complexity. The right scaffolding can impact the efficiency of a project and worker safety significantly. According to industry reports, over 70% of scaffolding-related accidents stem from improper assembly. Clear instructions matter.

Tips for selecting steel scaffolding include assessing materials and load capacities. Lightweight options may offer easier transport but can compromise stability. Check user reviews. Look for feedback on weight limits and ease of setup. Avoid models that seem to have frequent assembly issues. A balanced choice may enhance productivity but requires careful evaluation.

User experiences highlight that not all options are created equal. Some models boast quick assembly but lack sturdiness. Others emphasize durability but can overwhelm with their weight. Striking a balance between these aspects is crucial. Pay attention to online discussions where real users share lessons learned. Judging by user feedback, a well-informed decision can prevent costly mistakes.