What is Stainless Steel Wire Mesh and Its Uses?

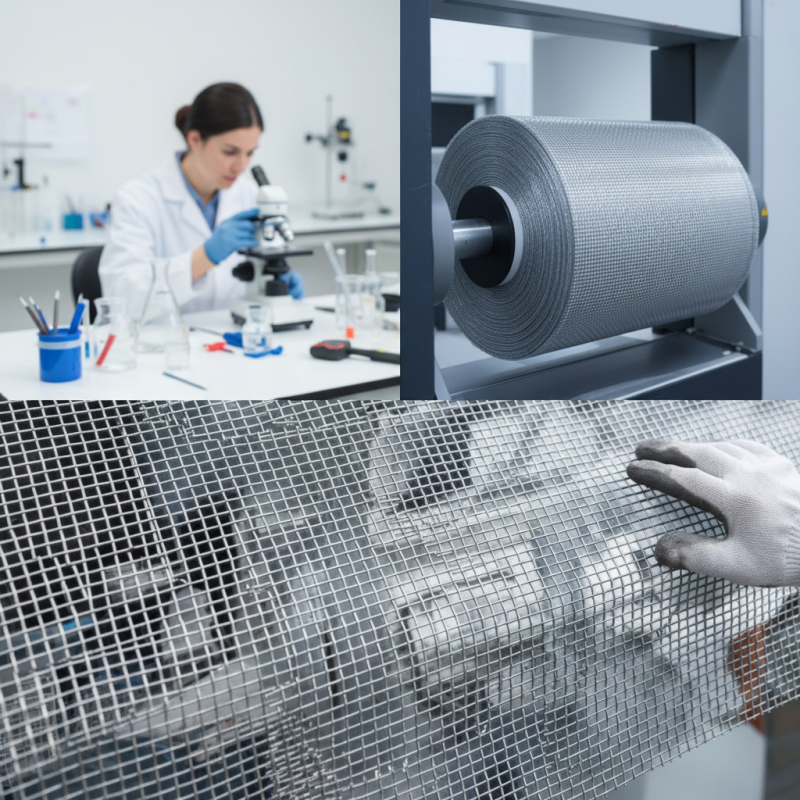

In the world of manufacturing and construction, stainless steel wire mesh stands out for its versatility and strength. Renowned expert Dr. Emily Carter in metallurgy states, "Stainless steel wire mesh combines resilience with adaptability." This combination makes it ideal for various applications across multiple industries.

stainless steel wire mesh is used in filtration, security, and architectural designs. Its corrosion resistance enables it to withstand harsh environments. The mesh comes in different sizes and shapes, making it customizable for specific needs. However, the production process can be challenging. Ensuring the balance between strength and flexibility often requires careful attention.

Despite its numerous benefits, some users may overlook the maintenance needs of stainless steel wire mesh. Regular checks for wear and tear are essential. It's not just about installation; ongoing care is crucial for longevity. This attention to detail can make a significant difference in performance. Acknowledging these aspects can help users maximize the advantages of stainless steel wire mesh.

Definition and Composition of Stainless Steel Wire Mesh

Stainless steel wire mesh is a versatile material widely used in various applications. Its definition centers on its composition, which typically includes a mixture of chromium and nickel. This combination enhances corrosion resistance and durability. The stainless steel used in wire mesh can vary, affecting its strength and flexibility.

The composition involves specific grades of stainless steel. These grades determine the wire mesh’s performance in different environments. For instance, 304 stainless steel is common, offering good corrosion resistance. Meanwhile, 316 stainless steel contains molybdenum, which provides enhanced protection against chloride environments. Understanding these differences is crucial for selecting the right type.

Details matter when using stainless steel wire mesh. It’s often employed in filtration, fencing, and architectural applications. The mesh size and weave pattern can significantly impact functionality. However, not all meshes suit every need. Real-world experiences reveal that improper selection leads to inefficiencies. There’s always a need to assess project requirements carefully to ensure reliability and effectiveness.

Manufacturing Process of Stainless Steel Wire Mesh

The manufacturing process of stainless steel wire mesh involves several key steps. Initially, raw materials are collected, typically including stainless steel wire of various grades. According to industry reports, about 70% of stainless steel wire parts use grade 304, known for its excellent corrosion resistance.

Next, the wire undergoes drawing. This reduces the wire's diameter and increases its length. A significant challenge during this stage is maintaining uniformity. Variations can affect the final product's strength and functionality. After drawing, the wire is cleaned to remove any contaminants, ensuring optimal adherence during weaving.

Weaving is the critical stage. Here, the wires are interlaced to create the mesh structure. The weave pattern can vary, affecting the mesh's characteristics. Often, plain weave is the most common type used in various applications. Reports indicate that after weaving, the mesh is often treated with coatings or finishes, enhancing durability. However, handling and cutting can sometimes lead to errors. These issues need addressing to meet quality standards. Overall, precision during each step is vital to ensure a high-quality final product.

Common Applications of Stainless Steel Wire Mesh

Stainless steel wire mesh is a versatile material used in various industries. It is made from high-quality stainless steel, ensuring durability and resistance to corrosion. This mesh is commonly employed in construction, filtration, and even agricultural applications. Its strength and flexibility make it suitable for many projects.

In construction, stainless steel wire mesh provides support in concrete applications. Contractors often use it to strengthen walls and floors. This mesh ensures stability and longevity. Additionally, it plays a crucial role in fencing. It keeps unwanted animals out while allowing air and light through. Its design can adapt to different landscapes.

In food processing, this mesh aids in filtration. It separates solid particles from liquids efficiently. The ease of cleaning ensures that hygiene standards are maintained. In agriculture, it's used for pest control and crop support. Farmers appreciate its longevity and resistance to harsh elements. However, choosing the right wire diameter can be challenging. It requires careful consideration based on specific needs.

Advantages of Using Stainless Steel Wire Mesh

Stainless steel wire mesh is widely recognized for its durability and versatility. It comes with a range of advantages that make it a preferred choice across various industries. According to recent industry reports, the stainless steel wire mesh market is projected to reach over $2 billion by 2025. This growth reflects its increasing use in construction, food processing, and filtration systems.

One key advantage is its corrosion resistance. Stainless steel can endure harsh environments that would damage other materials. This feature is vital in industries where hygiene is paramount, such as food processing. In fact, a study found that 75% of food manufacturers choose stainless steel mesh to maintain product integrity and safety.

Another important benefit is its strength. Stainless steel wire mesh can withstand significant tensile stress, making it suitable for demanding applications. Its durability minimizes the need for frequent replacements, saving costs in the long run. However, it is essential to choose the right grade of stainless steel to match specific applications, as not all grades perform equally well. Understanding these nuances can prevent costly mistakes and ensure optimal performance.

Different Types of Stainless Steel Wire Mesh Products

Stainless steel wire mesh comes in various types, each designed for specific applications. Common types include woven wire mesh, welded wire mesh, and perforated sheets. Woven wire mesh is made by crossing two wire strands. This creates a flexible yet strong structure, ideal for filtration and sieving. According to industry reports, woven wire mesh has a market share of approximately 25% in the overall wire mesh industry.

Welded wire mesh is more rigid. It's formed by welding intersecting wires together. This type is widely used in construction, agriculture, and fencing. The global demand for welded wire mesh is expected to grow by 10% annually.

Perforated sheets, on the other hand, are used for ventilation and aesthetic purposes. They feature strategically placed holes, offering both strength and style.

Different stainless steel grades are often used. For instance, 304 stainless steel is suitable for general-purpose applications. It's corrosion-resistant and easy to clean. Meanwhile, 316 stainless steel is used in marine environments, as it provides better resistance to saltwater. Some products do not perform as well under extreme conditions. Choosing the right type is crucial to ensure durability and performance.